Built using its own CoolGan tech, the part has passed the United States Defense Logistics Agency's highest reliability certification for the Joint Army Navy Space standard MIL-PRF-19500/794. It is the first GaN transistor Infineon has made entirely in its own foundry to hit that level.

These GaN high electron mobility transistors (HEMTs) are aimed at on-orbit vehicles, manned missions and deep space probes. Infineon reckons that pairing its 50-plus years in high-reliability with the brutal endurance of GaN HEMTs results in superior thermal handling, power density and efficiency. The transistors are meant to sit snugly alongside its older, silicon-based radiation-hardened MOSFETs, offering a broader portfolio for space kit makers.

Infineon senior vice president and general manager HiRel Chris Opoczynski said: "The Infineon team continues to push the limits of power design with our new GaN transistor line. This milestone brings the next-generation of high reliability power solutions for mission-critical defence and space applications that utilise the superior material properties of wide bandgap semiconductors to customers serving the growing aerospace market."

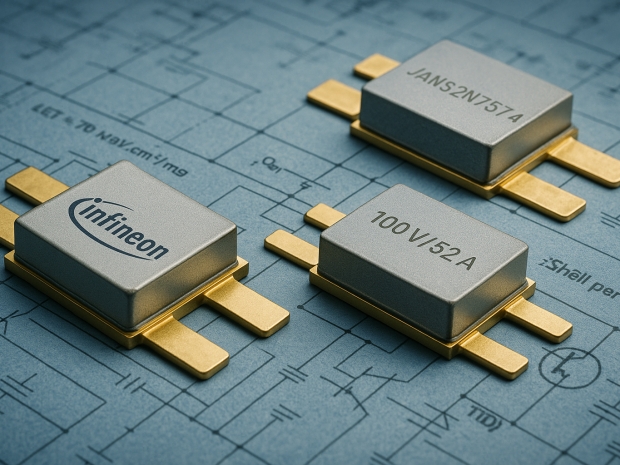

Three initial variants are out of the airlock already. They run at 100 volts and 52 amps, with a drain-source on resistance of just 4 milliohms and a gate charge of 8.8 nanocoulombs. They're also built in ceramic surface-mount packages, single event hardened up to 70 MeV.cm2/mg using gold ions. Two are not JANS certified but have been screened for total ionising doses up to 500 krad. The third, also screened to 500 krad, is the one officially certified under JANS.

Infineon is the first to get the DLA JANS thumbs-up for GaN devices made entirely in-house. The certification involves a soul-crushing amount of screening and quality checks that would make lesser outfits cry into their datasheets. It also says it's pumping out multiple batches pre-full release to keep long-term quality in check.

Engineering samples and eval boards are already available. The first certified JANS device lands in the summer of 2025, with more variants due soon offering wider ranges of voltages and currents for more design flexibility.